Causes of scratches on welded pipe blank caused by used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-19 11:30

- Pvs:

【概要描述】The tube blank scratches that appear in the welding of the used welded pipe machine are mainly caused by two parts, one is the guiding mechanism, and the other is the extrusion welding mechanism.

Causes of scratches on welded pipe blank caused by used welded pipe machine

【概要描述】The tube blank scratches that appear in the welding of the used welded pipe machine are mainly caused by two parts, one is the guiding mechanism, and the other is the extrusion welding mechanism.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-19 11:30

- Pvs:

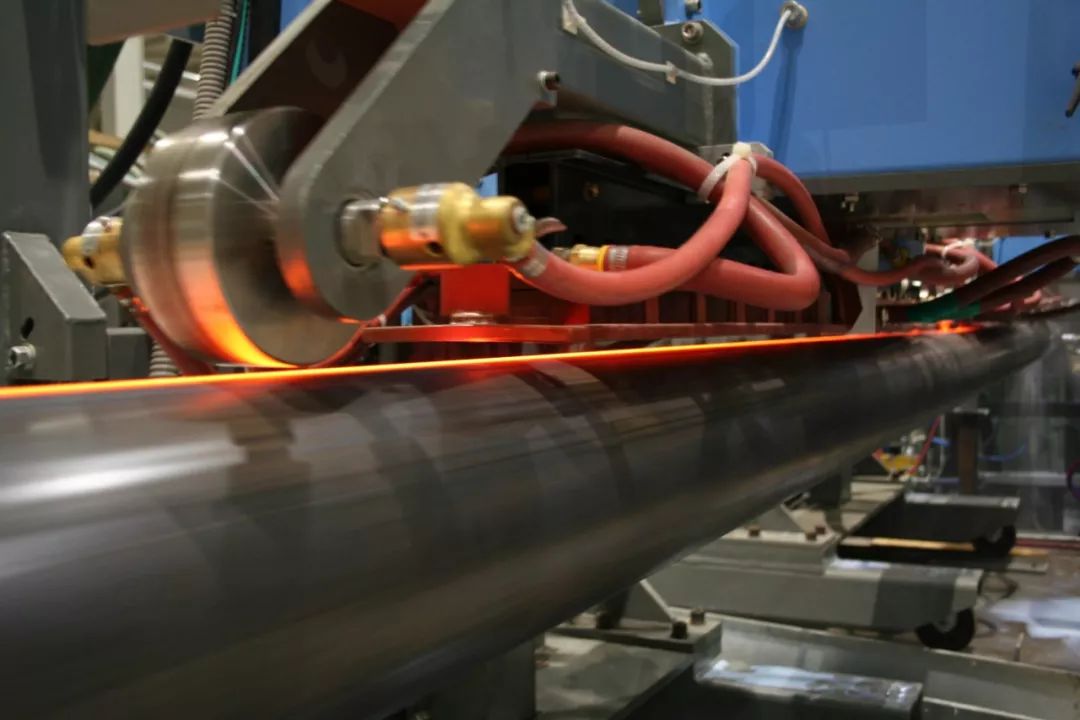

The tube blank scratches that appear in the welding of the used welded pipe machine are mainly caused by two parts, one is the guiding mechanism, and the other is the extrusion welding mechanism.

1. Scratch of the guide mechanism

The scratches of the guiding parts of the used welded pipe machine generally occur on both sides of the tube blank. If the guiding structure equipped with the guide sleeve is adjusted unreasonably, the upper and lower surfaces of the tube blank will also have frictional scratches. The characteristics of injuries are relatively large wounds and strong continuity. The main reason is that the height position of the guide sleeve is incorrect, or after the upper and lower guide roller bearings are damaged and replaced, the tube blank cannot be well controlled to cause friction with the guide sleeve to form. In addition, when the guide roll deviates too much from the rolling centerline, and the relative difference between the axis of the guide sleeve and the guide roll is too large, it will also cause scratches on both sides of the tube blank.

2. Scratch on the extrusion welding mechanism

The scratches caused by the squeeze roller of the used welded pipe machine mainly occur at the bottom of the tube blank. The reasons are roughly as follows:

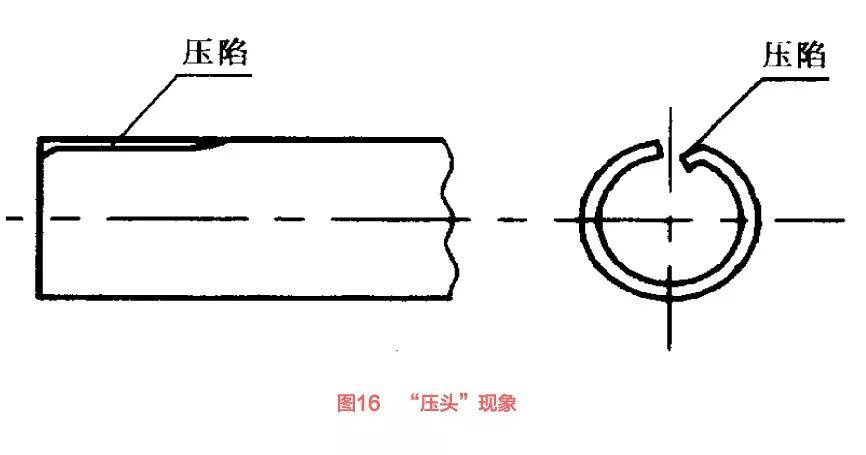

(1) The hole pattern does not match. There are two-roller, three-roller and four-roller welding seam extrusion structures. As long as the combined hole patterns do not match, it is easy to cause scratches on the surface of the tube blank. The two-roller structure is particularly prominent. There are many factors that cause the mismatch of the hole patterns. Take the two-roller structure as an example, such as damage to the bearing; axial movement of the roller; different hole patterns; different height positions of the two rollers; shaft bending and unstable assembly.

(2) Highly matching. The lower edge of the squeeze roll pass should be consistent with the height of the rolling line, and the height of the guide roll is determined by the wall thickness of the tube. If the height of the guide roller is reduced to a certain limit, the edge rounded corners of the squeeze roller pass will cause scratches on the bottom of the tube blank, especially after the R rounded corners of the squeeze roller pass are sharpened, the scratches will be It's more likely to happen.

(3)The squeeze force on the squeeze roller is insufficient. Especially for the squeeze roller device with two-roller structure, when the upper squeezing force is insufficient, under the tension of the tube blank, the roller shaft will have an upward elevation angle, so that the rounded corners of the hole edge R will protrude, resulting in the lower part of the tube blank. Scratched. When the rounded corners of the squeeze roll hole type R are sharpened, the occurrence of scratches will be aggravated.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province