Causes and solutions of tube size defects of used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-10 11:30

- Pvs:

【概要描述】The tube size defect of used welded pipe machine mainly points out that the size of the open tube after the final closed-hole type roll is too large or too small. Whether the opening is too large or too small, the tube to be welded will have an impact on the subsequent welding and sizing.

Causes and solutions of tube size defects of used welded pipe machine

【概要描述】The tube size defect of used welded pipe machine mainly points out that the size of the open tube after the final closed-hole type roll is too large or too small. Whether the opening is too large or too small, the tube to be welded will have an impact on the subsequent welding and sizing.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-10 11:30

- Pvs:

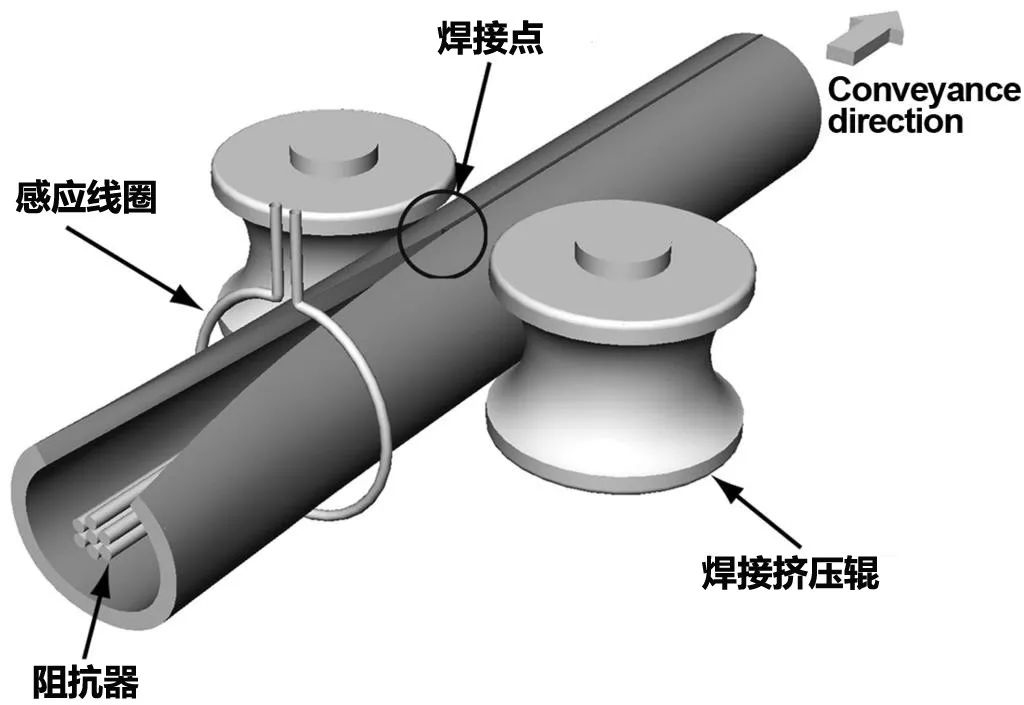

The tube size defect of used welded pipe machine mainly points out that the size of the open tube after the final closed-hole type roll is too large or too small. Whether the opening is too large or too small, the tube to be welded will have an impact on the subsequent welding and sizing.

①The size is too large.

(1) It will lead to an increase in the welding allowance, and most of the high-temperature molten metal originally used for welding will be extruded out of the weld, while the low-temperature molten metal will be extruded to form a weld, resulting in low strength of the weld due to cold welding;

(2) It will increase the burden on the hole shape of the extrusion roller, accelerate the wear and tear, and cause the extrusion roller to be easily burned and cracked;

(3) It will cause the upper and lower parts of the tube blank to be easily bitten by the edge of the extrusion roller hole, which will affect the surface quality of the welded tube;

(4) It will hinder the adjustment of the sizing size.

②The size is too small. The reduced welding allowance not only affects the strength of the weld, but also affects the sizing size and accuracy of the used welded pipe machine.

Causes of oversized or undersized tubes:

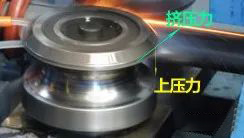

(1) Too little or too much pressure on the closed-hole flat roller;

(2) The degree of softness and hardness of the tube blank affects the size of the open tube. Under the premise of the same rolling force, the softer tube blank is easy to be pressed down, and the harder tube blank is difficult to be pressed down, which is why the hard material is opened. The important reason why the width of the material is relatively narrow;

(3) The opening width and thickness tolerances vary greatly.

In summary, it is necessary to appropriately adjust the reduction amount of the closed-hole flat roll and the shrinkage of the vertical roll according to the process requirements of the used welded pipe machine and the hardness and width of the pipe blank, so as to control the size of the pipe to be welded.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province