Analysis of the factors affecting the pipe making process of high frequency welded pipe equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-15 11:30

- Pvs:

【概要描述】The main process parameters of high-frequency straight seam welded pipes manufactured by high frequency welded pipe equipment include welding heat input, welding pressure, welding speed, size of opening angle, position and size of induction coil, position of impedance and other. These parameters have a great impact on improving the product quality, production efficiency and unit capacity of high-frequency welded pipes. Matching various parameters can make manufacturers obtain considerable economic benefits.

Analysis of the factors affecting the pipe making process of high frequency welded pipe equipment (2)

【概要描述】The main process parameters of high-frequency straight seam welded pipes manufactured by high frequency welded pipe equipment include welding heat input, welding pressure, welding speed, size of opening angle, position and size of induction coil, position of impedance and other. These parameters have a great impact on improving the product quality, production efficiency and unit capacity of high-frequency welded pipes. Matching various parameters can make manufacturers obtain considerable economic benefits.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-15 11:30

- Pvs:

The main process parameters of high-frequency straight seam welded pipes manufactured by high frequency welded pipe equipment include welding heat input, welding pressure, welding speed, size of opening angle, position and size of induction coil, position of impedance and other. These parameters have a great impact on improving the product quality, production efficiency and unit capacity of high-frequency welded pipes. Matching various parameters can make manufacturers obtain considerable economic benefits.

2 . Welding pressure (reduction amount)

The welding pressure is one of the main parameters of the welding process of the high frequency welded pipe equipment. After the edge of the strip is heated to the welding temperature, the metal atoms are combined with each other under the action of the squeezing roller to form a weld. The size of the welding pressure affects the strength and toughness of the weld. If the applied welding pressure is too small, the welding edges cannot be fully fused, and the residual metal oxides in the welding seam cannot be discharged to form inclusions, which will greatly reduce the tensile strength of the welding seam and cause the welding seam to crack easily after being stressed; if the applied welding pressure If it is too large, most of the metal reaching the welding temperature will be extruded, which not only reduces the strength and toughness of the weld, but also produces defects such as excessive internal and external burrs or lap welding.

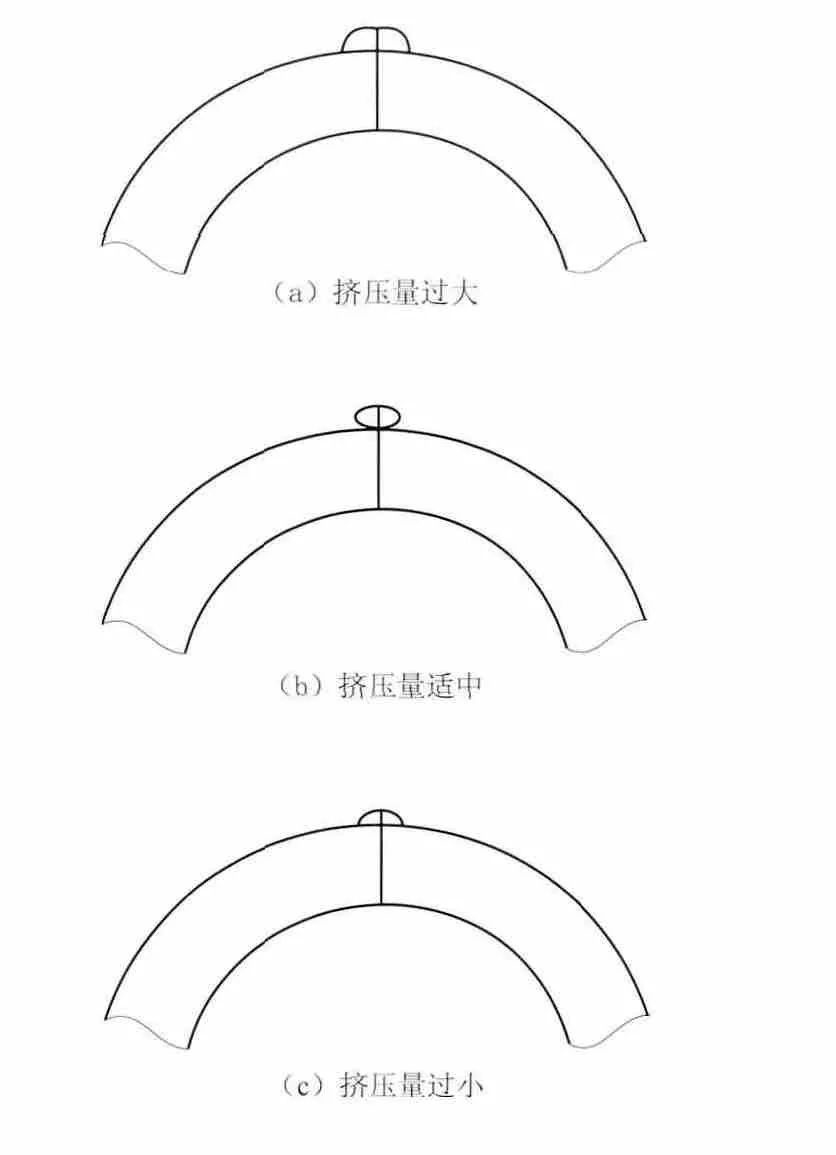

The welding pressure is generally measured and judged by the diameter change of the steel pipe before and after the extrusion roller and the size and shape of the burr. The effect of welding extrusion force on burr shape is shown in Figure 3.

Figure 3 Influence of welding extrusion force on burr shape

Analysis of the influence of high frequency welded pipe equipment on pipe welding control:

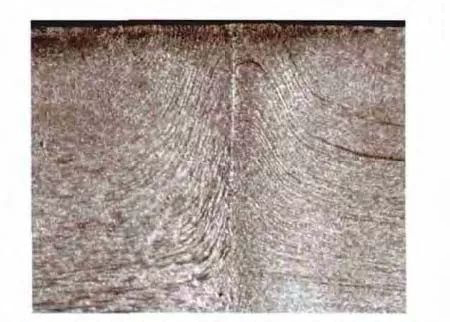

The welding extrusion amount is too large, the spatter is large and the molten metal is extruded, the burr is large and overturns on both sides of the weld; the extrusion amount is too small, there is almost no spatter, the burr is small and it is piled up; When it is moderate, the extruded burr is upright, and the height is generally controlled at 2.5~3mm. If the welding extrusion amount is properly controlled, the metal streamline angle of the weld is basically symmetrical up and down, left and right, and the angle is 55°~65°. When the extrusion amount is properly controlled, the shape of the metal streamline of the weld is shown in Figure 4.

Figure 4 The shape of the metal streamline of the weld when the extrusion amount is properly controlled

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province