Analysis of high frequency current of used HFW pipe machines

- Sort:Information

- Auth:

- Source:

- Release time:2023-01-30 11:30

- Pvs:

【概要描述】The application in the field of welding of used HFW pipe machines is an alternating current frequency of 100 kHz to 800 kHz. The power frequency of 50 or 60 Hz is first converted to DC, which is converted to high frequency by using an oscillation formed by vacuum tubes combined with tank capacitors or by inverters consisting of high frequency power crystal devices MOSFETs (Metal Oxide Field Effect Transistors). Alternating current, through the output device to form a heating source for steel pipe welding.

Analysis of high frequency current of used HFW pipe machines

【概要描述】The application in the field of welding of used HFW pipe machines is an alternating current frequency of 100 kHz to 800 kHz. The power frequency of 50 or 60 Hz is first converted to DC, which is converted to high frequency by using an oscillation formed by vacuum tubes combined with tank capacitors or by inverters consisting of high frequency power crystal devices MOSFETs (Metal Oxide Field Effect Transistors). Alternating current, through the output device to form a heating source for steel pipe welding.

- Sort:Information

- Auth:

- Source:

- Release time:2023-01-30 11:30

- Pvs:

When it comes to the frequency of used HFW pipe machines, we must first explain what is high-frequency

The application in the field of welding of used HFW pipe machines is an alternating current frequency of 100 kHz to 800 kHz. The power frequency of 50 or 60 Hz is first converted to DC, which is converted to high frequency by using an oscillation formed by vacuum tubes combined with tank capacitors or by inverters consisting of high frequency power crystal devices MOSFETs (Metal Oxide Field Effect Transistors). Alternating current, through the output device to form a heating source for steel pipe welding.

Therefore, in short, the steps of converting power frequency to high frequency are: power frequency AC (rectification) -> DC (oscillation/inversion) -> high frequency AC

The characteristics of the high frequency current of the used HFW pipe machines:

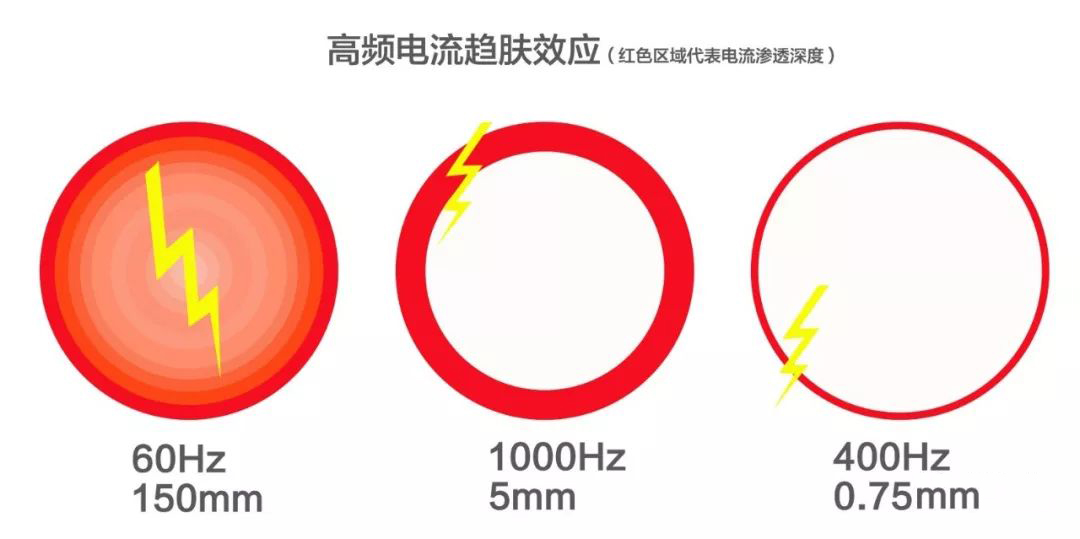

High frequency currents have two unusual characteristics compared to 50 or 60 Hz power frequency currents. First of all, the power frequency current flows through the entire section of the metal conductor (current carrier), while the high-frequency current only flows on the surface of the metal conductor (current carrier). The higher the frequency, the lower the carrier section utilization. This property is called the "skin effect".

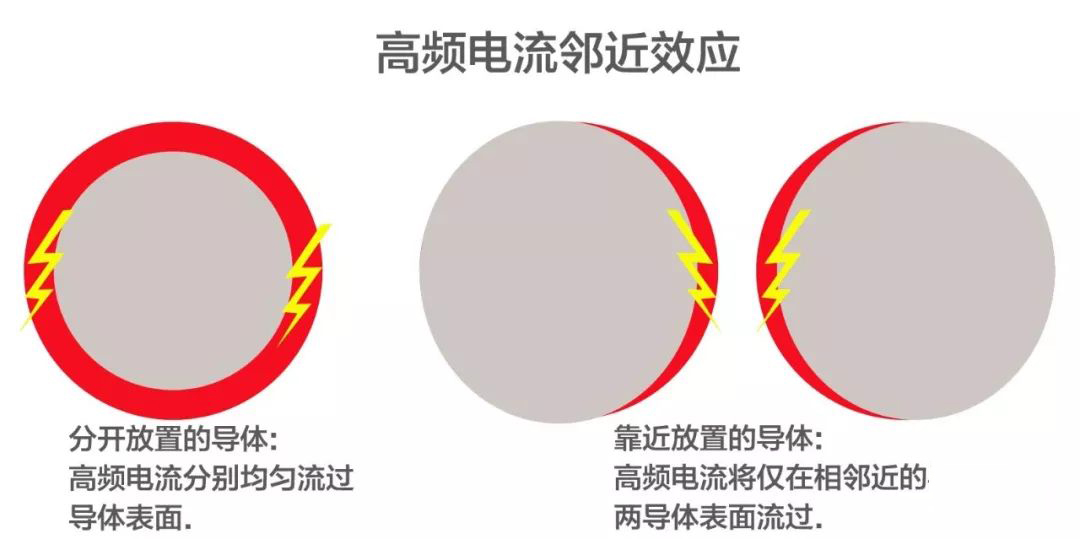

Second, when the two conductors carrying high-frequency current are close to each other, the high-frequency current will flow uniformly on the entire surface of the metal conductor, and the current will only flow on the adjacent surfaces of the two conductors. This property is called the "proximity effect".

The relationship between high frequency current and welding

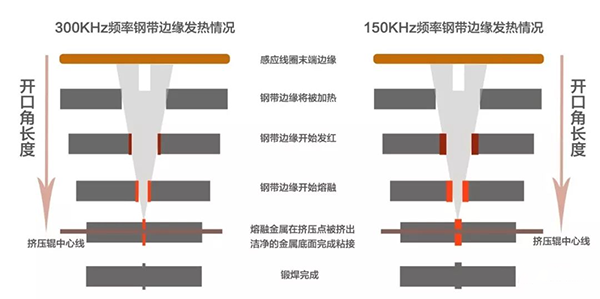

The high-frequency current of the used HFW pipe machines is very suitable for welding steel pipes. Because of its skin effect, the current only flows on the surface and only a small amount of the edge surface of the metal strip is heated. A small amount of heat forms a very narrow heat affected zone (HAZ) that can heat the metal surface to a high enough level temperature.

The heat-affected zone (HAZ) is the part of the weld, distributed on both sides of the bond line, that is heated to a high enough temperature without melting and has changed its own crystalline structure.

The proximity effect helps concentrate the current to flow towards the two strip edges that are getting closer and form the Vee angle. Make the work process more efficient. The Vee weld area formed by the edge of the strip in front of the squeeze rolls must be carefully controlled for maximum current utilization.

Mill set-up problems such as poor roll alignment, shaft deformation, and excessive roll wear can cause the Vee angle to drift from side to side or cause the strip edge to move up and down, side to side. When these phenomena occur, the characteristics of proximity effect will lead the current and change the distribution and current intensity of the current flowing at the edge of the steel strip, thereby causing temperature changes, resulting in welding quality problems. High frequency currents are very sensitive at this point.

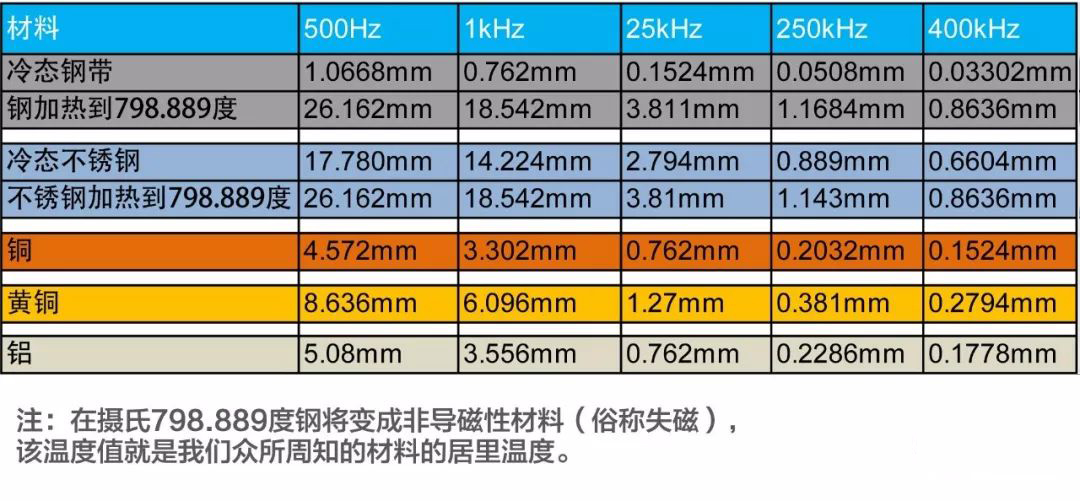

The relationship between frequency and skin depth

High-frequency skin depth is the comprehensive performance of material properties, material temperature properties and frequency properties. Generally higher frequencies will have a shallower skin depth, and lower frequencies will have a deeper skin depth. The skin depth is usually measured by the reference depth, and this parameter can be theoretically calculated by the following formula.

d=3160√(r/mf)

d = reference depth

r = resistivity of the heated material

f = frequency

m = material permeability

Note: 3160 is the constant constant of steel, different materials have different constant constants.

The most commonly used welding frequency for high-frequency welding of used HFW pipe machines is 400 kHz. However, for very small diameter and very thin wall high frequency welded pipes, higher frequencies will be more beneficial for welding. High-frequency welded pipes with large wall thicknesses (above 16mm) are easy to use relatively low frequencies, usually in the frequency range of 120 kHz to 250 kHz.

The relationship between frequency and skin depth

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not assume relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province