Analysis of common faults of used welded pipe equipments sizing machine (3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-06 11:30

- Pvs:

【概要描述】In order to let everyone understand the common faults of used welded pipe equipments sizing machines, we analyze the common faults of used welded pipe equipments sizing machines on this issue - the pipe is not round.

Analysis of common faults of used welded pipe equipments sizing machine (3)

【概要描述】In order to let everyone understand the common faults of used welded pipe equipments sizing machines, we analyze the common faults of used welded pipe equipments sizing machines on this issue - the pipe is not round.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-06 11:30

- Pvs:

In contrast, the failure rate of the sizing machine is the lowest, and it is easier to deal with. The common production accidents of the used welded pipe equipments sizing machine are as follows: ① Scratches. ②Drilling pipe. ③The pipe is not round.

In order to let everyone understand the common faults of used welded pipe equipments sizing machines, we analyze the common faults of used welded pipe equipments sizing machines on this issue - the pipe is not round.

The tube is not round

The shapes of non-circular tubes are generally oval, ribbed and gourd-shaped.

① Oval

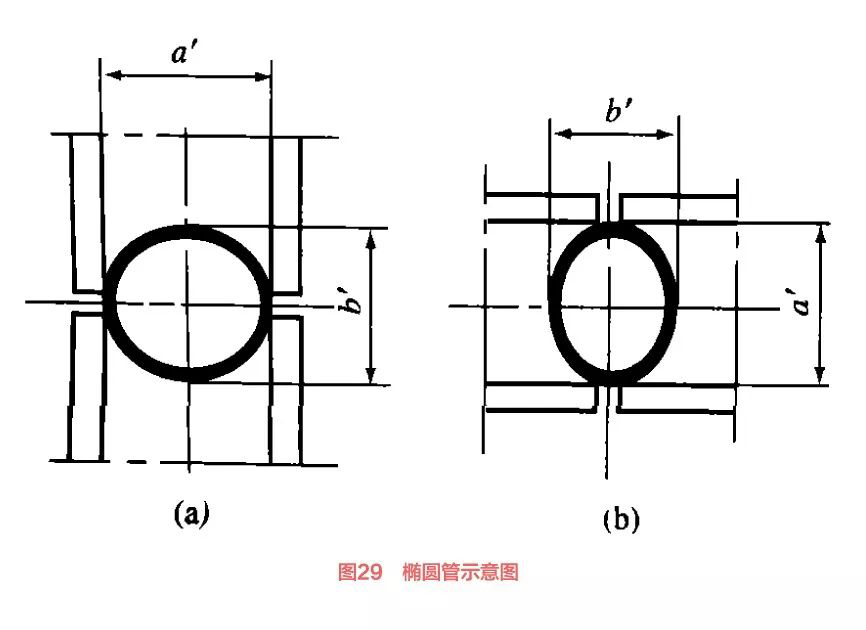

The oval tube is completely caused by improper adjustment of the sizing hole, especially after the sizing hole has a certain wear, unreasonable adjustment will make the pipe more likely to appear elliptical. In general, elliptical tubes that occur on the transverse and longitudinal axes of the tube section (Fig. 29),

It is caused by the unreasonable matching of the pressure between the flat roll and the vertical roll. The pressure can be appropriately increased in the long axis direction of the elliptical tube and reduced in the short axis direction.

If the axis of the elliptical tube has an inclined angle (Fig. 30),

It should be adjusted according to the actual situation. For example, when the elliptical tube caused by the flat roll and the vertical roll is in the same direction, the steering adjustment method can be used. By pressing down one side of the flat roll, the tube is rotated in a certain direction, and then the pressure of the vertical roll and the pressure of the vertical roll can be increased or decreased. adjust. This kind of elliptical tube is a typical example that is difficult to adjust. If the steering method cannot solve the problem, the method of hole type transposition can also be carried out. That is to say, remove the two vertical rollers and change the position, so that the elliptical tube from the flat roller hole forms an opposite direction, and then adjust the increase and decrease force. Or it is also possible to change the direction of the pass pattern of the upper flat roll, so that the worn pass pattern of the flat roll can be recombined. The direction of the long axis of the pass of the lower roll opposite to the axial direction. Of course, this is a treatment that is only used when other methods fail to solve the elliptical tube.

② Ribbed round tube

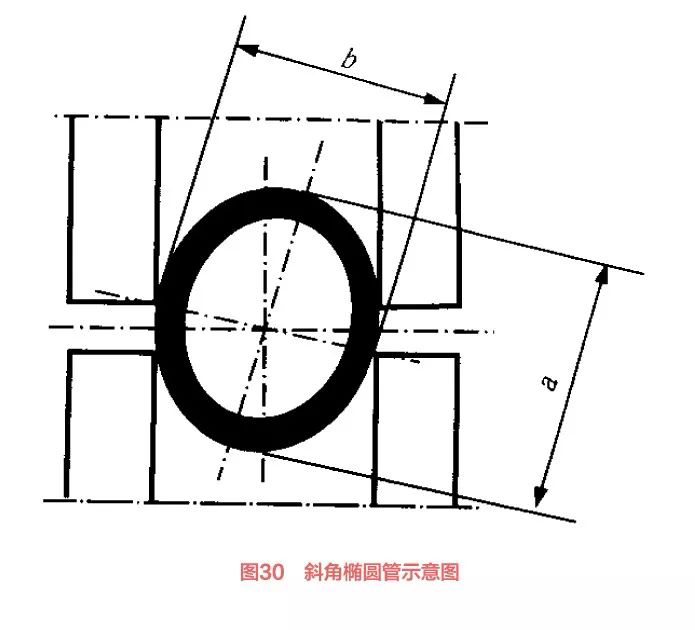

The ribbed round tube refers to a certain part of the round surface of the tube with a protruding rib shape (Figure 31),

We call it a prismatic tube. Generally, there are the following reasons for the production of this kind of tube.

(1) Poor forming deformation

This situation should not occur in the early stage of the use of the hole pattern. After the middle and later stages, the hole pattern is sometimes used unreasonably, and the hole pattern arc surface has irregular deformity and wear. This undesirable deformation produces prismatic tubes. When the machine is stopped for inspection, we can touch the outer arc surface of the deformed tube blank one by one with the palm of our hand, and we can feel whether the tube blank is abnormally deformed.

(2) Sizing hole wear

The wear of the sizing hole is one of the most important reasons for the round pipe caused by the wear of the sizing hole, especially when some slight peach-shaped pipes are often produced, but cannot be solved in time, the A certain part of the sizing hole type will be specially worn, so that a concave arc surface will be formed in this part, resulting in the appearance of a ribbed round tube. This requires us to deal with and solve some bad forming deformation problems and the production of peach-shaped pipes as soon as possible, and often check the wear of the sizing hole, and replace it in time when it is found that the arc of the hole has irregular wear.

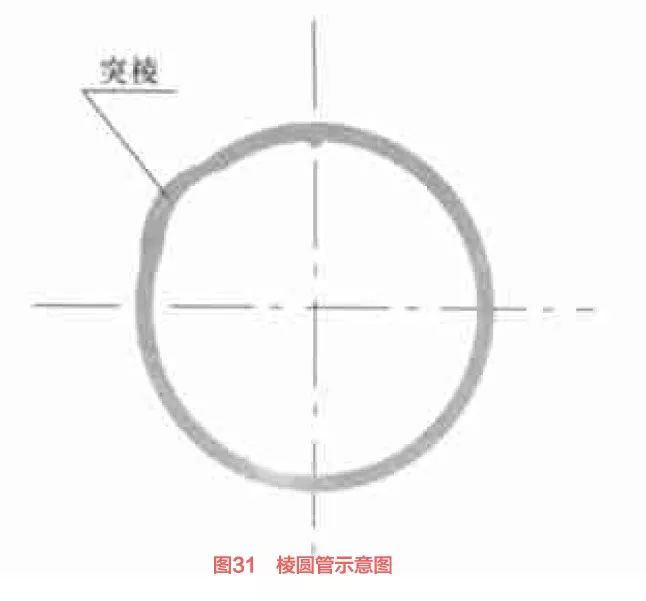

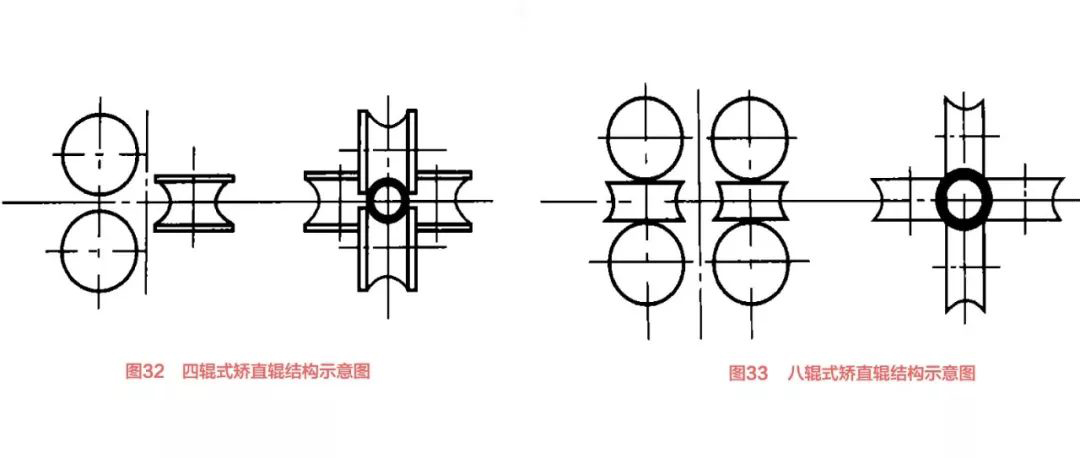

(3) Uneven force on the straightening roller

There are basically two types of straightening roller structure, one is a four-roller structure (Figure 32), and the other is an eight-roller structure (Figure 33).

The cause of the angular round tube is generally caused by the straightening roller of the eight-roll structure. When the pipe is straightened, the overall adjustment should be carried out according to the adjustment process requirements, so that the contact force between each roller and the pipe surface is very light. If the single-roller adjustment is performed, the circular shape formed by every four rolls will be destroyed, and under the pressure of the single-roller, a strange angular surface will appear on the surface of the tube.

③ Gourd pipe

Sometimes when we check the outer diameter of the pipe, we will find that the diameter of the pipe is thick and thin, and the thickness error can be up to about 0.3 mm, commonly known as the gourd pipe. This is mainly caused by the following two situations.

(1) Bearing damage

When the flat roll bearing is slightly damaged, with the rotation of the roll, the residual dead point of the jam may sometimes occur. When the pressure of the roll changes and cannot be constant, the outer diameter of the tube is controlled. The same changes will occur, and the tube will have a cycle-unstable gourd-like size. But as long as the bearing rotates stably, even when the bearing is damaged, it will not bring too much adverse effect on the outer diameter of the tube.

(2) Flat roll shaft bending

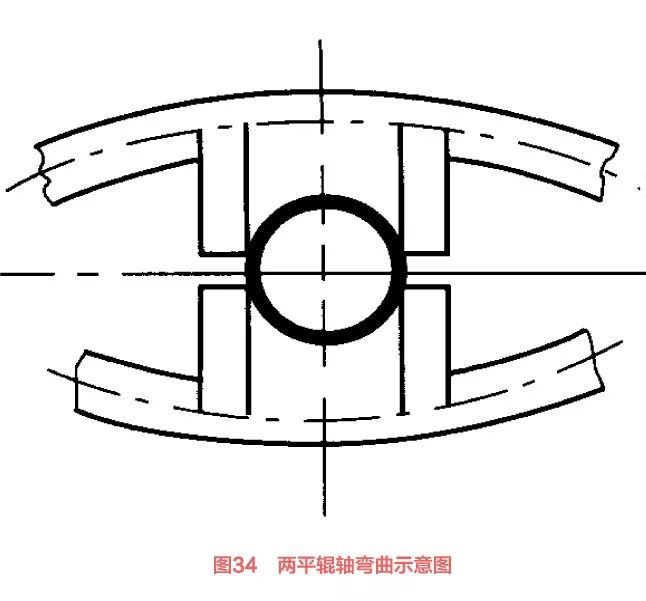

Bending of the flat roller shaft Due to special reasons such as the drill pipe, after the flat roller shaft is damaged by a large external force, the bending amount of the shaft exceeds the limit of its elastic deformation and cannot be restored, at the position of the hole pattern, between the two shafts The distance has changed (Figure 34).

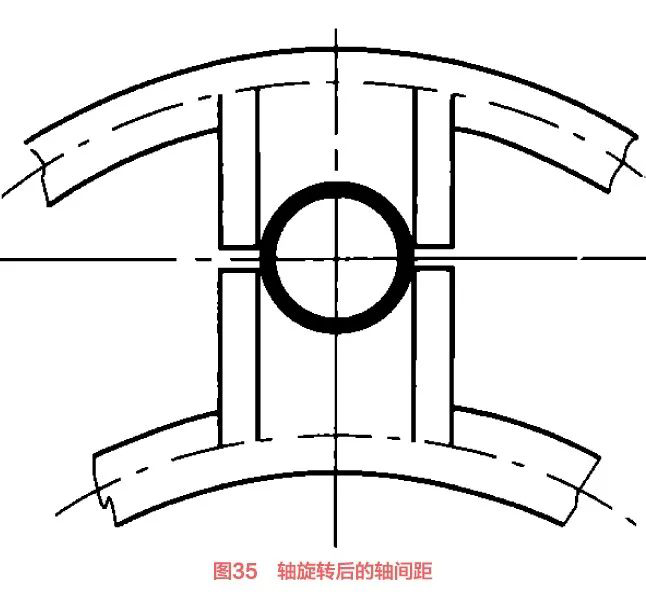

With the rotation of the rolls, the distance between the axes also changes, so that the diameter of the pipe also appears larger and smaller. And this kind of gourd pipe is periodically stable and equidistant. When solving this problem, we first check the radial runout of the roll, from which we can judge whether both the upper and lower shafts are bent, or only one shaft is bent. If both shafts are bent, one of the shafts can be rotated 180° before installation and use (Figure 35)

In this way, the same inter-axis distance between the two axes can always be maintained when the two axes are rotated. If a shaft is bent, it is necessary to replace a new shaft, or reduce the pressure of the flat roller on the tube.

If the used welded pipe equipments has common faults in the sizing machine, and the pipe is not round, pay attention to these three pipe shapes ① Ellipse. ② The edge is round. ③ Gourd shape. Hope to be of some help to you. Our company has many brands and wide resources, there is always one suitable for you. You only need to inform us of your pipe manufacturing needs, and our company will provide you with used welded pipe equipments that really suits your needs. Welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province