Advantages and disadvantages of the used roll forming machine forming method - integral forming

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-17 11:30

- Pvs:

【概要描述】The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the second-hand roll forming machine.

Advantages and disadvantages of the used roll forming machine forming method - integral forming

【概要描述】The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the second-hand roll forming machine.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-17 11:30

- Pvs:

The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the used roll forming machine.

In the used roll forming machine, it is necessary to go through 5 basic processes: edge bending - overall bending - closed opening - extrusion welding - sizing. In the welded pipe industry, the three processes before high-frequency welding are generally referred to as preforming. The forming methods of the used roll forming machines can be divided into edge forming and integral forming.

2.Overall molding

The overall bending is the second step of the high-frequency welded pipe forming of the used roll forming machine, and its purpose is to bend the pipe as a whole to the curvature of the closed introduction roll. The traditional overall bending is formed by alternating flat/vertical roller hollow bending. The modern advanced integral forming process adopts row-roll forming concentrated hollow bending forming, and the FFX forming process adopts involute vertical roller cluster hollow bending to realize integral forming.

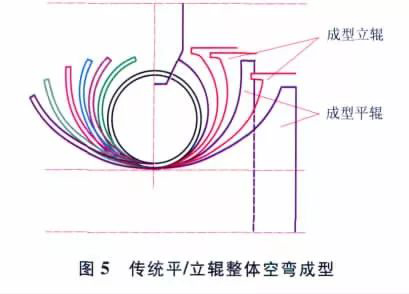

①Flat/vertical roll alternate forming

The pass and strip formed alternately by flat/vertical rollers are closed hollow bends. The flat rolls and vertical rolls are alternately arranged, the flat roll is the active roll, the vertical roll is the passive roll, and the flat roll and the vertical roll perform empty bending one by one, as shown in Figure 5.

The advantages of alternating flat/vertical roll forming: good formability, uniform and stable forming force distribution, good strip neutrality, and not easy to deviate from the rolling center.

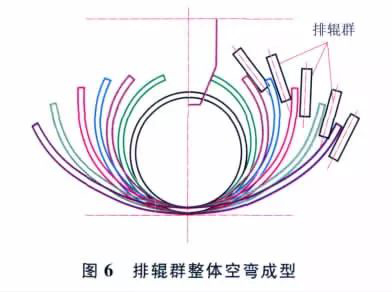

②Forming in row roller group/involute vertical roller group

The holes and strips formed in the row roller group/involute vertical roller group are open hollow bends. The strip is continuously concentrated and hollowed by the row roller group or the involute vertical roller group, as shown in Figure 6.

The advantages of forming in the row roller group/involute vertical roller group are: easy for the strip to enter the hole pattern, the surface is not easy to be scratched, the forming route is short, and the rollers have good commonality.

Disadvantages: The structure of the frame is complex and the adjustment is difficult; the row roller group/vertical roller group is non-power transmission, and can only be pushed into the pass by external force; the row roller group relies on the blocking roller to prevent the strip from deviating from the rolling center, which is easy to cause the strip. The edges are thickened.

Summarize:

When the used roll forming machines is used for the welded pipe process, the overall forming process will occur. Among them, the solid bending hole type has two basic types: flat/vertical roller alternate forming, row roller group/involute vertical roller cluster forming.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province