Advantages and disadvantages of forming method of used roll forming machines - edge forming

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-14 11:30

- Pvs:

【概要描述】The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the second-hand roll forming machine.

Advantages and disadvantages of forming method of used roll forming machines - edge forming

【概要描述】The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the second-hand roll forming machine.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-14 11:30

- Pvs:

The high-frequency welded pipe forming roll is an important part of the used roll forming machines, and it is also the technical core of the welded pipe forming process. At the same time, judging the quality of the welded pipe depends on the pipe forming method of the used roll forming machine.

In the used roll forming machines, it is necessary to go through 5 basic processes: edge bending - overall bending - closed opening - extrusion welding - sizing. In the welded pipe industry, the three processes before high-frequency welding are generally referred to as preforming. The forming methods of the used roll forming machines can be divided into edge forming and integral forming.

1. edge molding

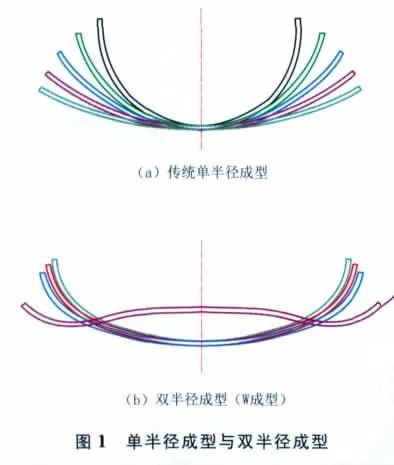

Edge forming is the first step in the forming process and its purpose is to bend the edge portion of the strip to the curvature of the extrusion roll radius. The traditional used roll former process uses single-radius forming for edge forming, and the modern process uses double-radius forming, as shown in Figure 1.

The initial double-radius molding was just a simple double-radius upward bending, and later developed into W molding. The bending of the middle part of this molding method adopts a reverse protrusion, which makes the edge more fully curved, and the lines around the hole shape during molding are formed. The speed difference is small.

Edge forming generally adopts the solid bending method. In cold bending, solid bending generally refers to the bending of the strip under stress on both sides, and the empty bending is bending under one side of the force. In edge forming, there are three basic types of solid curved hole types: single radius, multi-curve and involute.

①Single radius solid bending forming

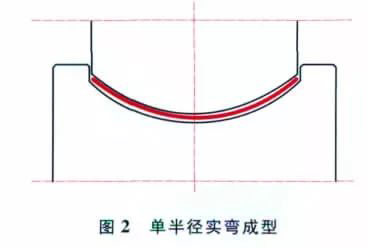

The hole shape and the strip formed by single-radius solid bending are in line contact closed type, and the strip is pushed into the hole shape by external force and then bent to form. The pass of this roll is a single radius of curvature, which can only bend the radius of curvature of a specific specification, and the rolls have no commonality, as shown in Figure 2.

The advantages of single-radius solid bending forming: The strip is well centered and guided, and it is not easy to deviate from the rolling center; the bending strip is subjected to a large forming force from the upper and lower rolls, the bending is sufficient, and the elasticity of the forming area is small; the roll pass curve is simple and easy to process .

Disadvantages: poor commonality of rolls; large difference in line speed on the pass pattern, which easily leads to scratches on the pass pattern and the surface of the strip; it is difficult for the strip to enter the cavity.

② Multi-curve solid bending forming

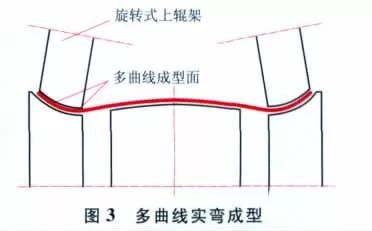

The pass and strip formed by multi-curve solid bending are line contact closed type, but the pass form of the upper and lower rolls has become a multi-section curve with different curvature radii. There is a certain degree of commonality. The upper part of the multi-curve forming frame should adopt a rotatable structure, and the used roll forming machines can select the required forming curvature by adjusting the angle; As shown in Figure 3.

The advantages of multi-curve solid bending: The rollers have a certain range of commonality; the adjustment is more convenient; the contact surface between the pass and the strip is small, and the surface is not easy to be scratched.

Disadvantages: The pass curve is more complex, and the processing is difficult; the frame structure is more complex; the strip center is easy to deviate from the rolling center, and the forming elasticity is large.

③ Involute solid bending forming

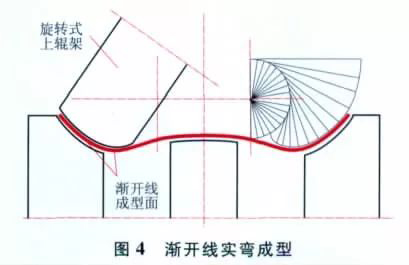

The hole pattern formed by involute solid bending is point-contact open type with the strip, the hole pattern of the upper roll is involute, the hole pattern of the lower roll is an arc or even a straight line with a large curvature radius, and the strip roll is bent and formed against the upper roll. Therefore, this method is also called "roll-to-roll molding". The upper and lower frames of the involute forming are generally rotary structures with adjustable angles, as shown in Figure 4.

The advantages of involute solid bending forming: the roll sharing is the best; the surface speed of the strip is poor, which avoids scratches.

Disadvantages: It is difficult to process the roll; the frame structure is complex; the manufacturing precision is very high; the strip center is easy to deviate from the rolling center, and the forming elasticity is large.

Summarize:

When the used roll forming machines is used for the welded pipe process, the edge forming process will occur, and the solid bending hole type has three basic types: single radius, multi-curve and involute.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province