Adjustment of Welding Squeeze Roller for high frequency welded pipe machine (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-22 11:30

- Pvs:

【概要描述】In the production of high frequency welded pipe machine, the forming joint state of the tube blank directly affects the quality of the weld, and the parallelism of the butt surface of the welded joint is particularly important. In the process of seam welding of steel pipes, the parallelism of the seam is mainly ensured by adjusting the reduction amount of the upper roller of the squeeze roller and the gap between the two upper rollers.

Adjustment of Welding Squeeze Roller for high frequency welded pipe machine (2)

【概要描述】In the production of high frequency welded pipe machine, the forming joint state of the tube blank directly affects the quality of the weld, and the parallelism of the butt surface of the welded joint is particularly important. In the process of seam welding of steel pipes, the parallelism of the seam is mainly ensured by adjusting the reduction amount of the upper roller of the squeeze roller and the gap between the two upper rollers.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-22 11:30

- Pvs:

In the production of high frequency welded pipe machine, the forming joint state of the tube blank directly affects the quality of the weld, and the parallelism of the butt surface of the welded joint is particularly important. In the process of seam welding of steel pipes, the parallelism of the seam is mainly ensured by adjusting the reduction amount of the upper roller of the squeeze roller and the gap between the two upper rollers.

3. Adjustment skills in special circumstances

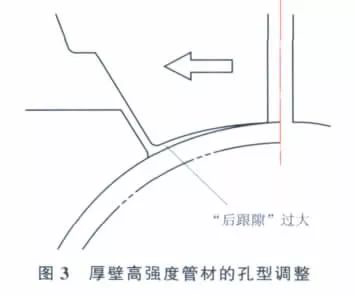

3.1 Adjustment of hole shape of thick-walled and high-strength pipes

The larger the wall thickness of the steel pipe, the higher the material strength, and the less easy it is to eliminate the V-shaped seam that occurs during welding. If obvious indentation has been formed on the outer surface of the upper roller but the I-shaped seam cannot be achieved, it means that the adjustment has reached the limit, and continuing to press the upper roller will not only cause serious indentation, but also form more serious V-shaped butt seam.

The above phenomenon indicates that a larger "heel clearance" is required to allow for a larger amount of depression adjustment. To this end, the gap between the two upper rollers can be enlarged to achieve this purpose.

It should be noted that the ideal upper roll gap value varies with the wall thickness and strength of the steel pipe. For example, in the case of thin wall thickness, it is generally necessary to set a smaller upper roll gap to improve the welding stability. If the wall thickness is thick, even if the gap between the upper rolls is appropriately expanded, the stability of the welding will not be affected. Therefore, in order to obtain a larger "heel gap" when forming thick-walled or high-strength steel pipes, the practice of expanding the gap between the upper rolls will not affect the stability of the welding as long as the expansion is appropriate.

The standard setting value on the hole pattern is selected by the designer based on years of practical experience, and usually can take into account different wall thicknesses and strengths. However, if the above-mentioned adjustment range is insufficient in the high frequency welded pipe machine, appropriately expanding the gap between the upper rolls can solve the problem to a large extent.

There are two limits of this adjustment method. Either the outer side of the upper roll has interfered with the vertical roll, and the gap cannot continue to be expanded; or the gap between the upper roll is too large, which has caused instability in the welding. In either case, it means that the structural design of the squeeze roll needs to be modified to obtain a larger set "heel gap". The adjustment in the case of thick-walled high-strength steel pipe is shown in Figure 3.

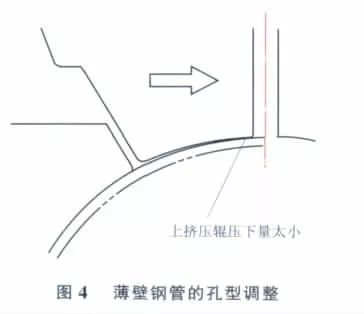

3.2 Pass adjustment of thin-walled steel pipes For thin-walled steel pipes, usually I-shaped butt joints can be obtained without excessive upper roll reduction. A frequent problem is the stability of the formed seam when welding. The hole type adjustment of thin-walled steel pipe is shown in Figure 4.

The stability of the forming seam is related to many factors, but a proper reduction of the upper roll gap will generally have the effect of improving the stability of the forming seam. Therefore, it is possible to take advantage of the fact that thin-walled steel pipes do not need a large "heel gap", and when the forming joint is unstable, the method of appropriately reducing the upper roll gap can be used to solve the problem.

4. Confirmation method of forming seam butt joint state

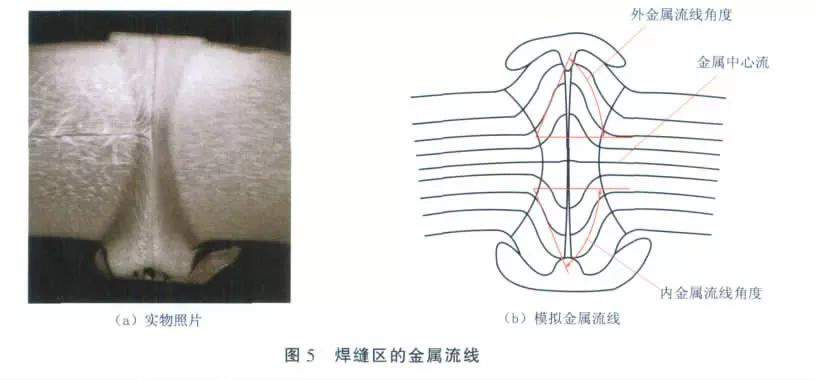

Observing the metal flow line in the welding area of the cross-section is the most accurate method to confirm the state of the formed seam during welding. This method can not only judge the joint state, but also judge whether the welding extrusion amount and welding output power are reasonable or not.

In order to facilitate the observation of streamlines, the test specimen shall be taken before the heat treatment of the weld. If the angles of the metal streamlines on the upper and lower parts of the weld are basically symmetrical, it can be judged that the seam of the butt surface is parallel (I-shape). Taking the middle of the wall thickness as the symmetry plane, the difference between the streamline angles of the upper and lower symmetrical parts usually needs to be limited to within 5°, and the "waist drum" shape of the heat affected zone should also be basically symmetrical downward. The metal streamlines in the weld zone are shown in Figure 5.

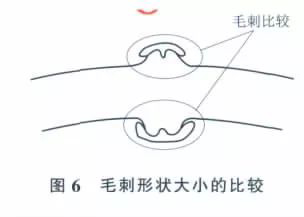

The easiest confirmation method on site is to compare the shape and size of the internal and external burrs after welding, as shown in Figure 6. If the seam is I-shaped, the size and shape of the inner and outer burrs are basically the same. On the high frequency welded pipe machine production line, the burr observation method is the most intuitive, but this method cannot be quantified and can only be used as a rough judgment.

If possible, it is recommended to use the streamline observation method to observe the metallographic phase of the cut piece, but the production of the sample generally takes a long time, and waiting for the result will often seriously affect the work efficiency on site. For this reason, the following relatively simple seam state confirmation method is often used. Although this method cannot obtain very accurate results, it can generally make a more accurate judgment on the seam state, which can greatly reduce the streamline observation method. Time to wait for results.

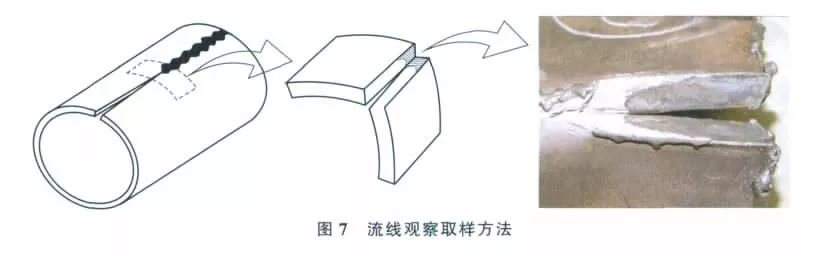

Sampling is first performed as shown in FIG. 7 . (note the sampling location)

It should be noted that the power output of the welding machine must be stopped before stopping. Otherwise, the contact mode and heating mode resulting in a joint will be different from the mode of steady-state welding.

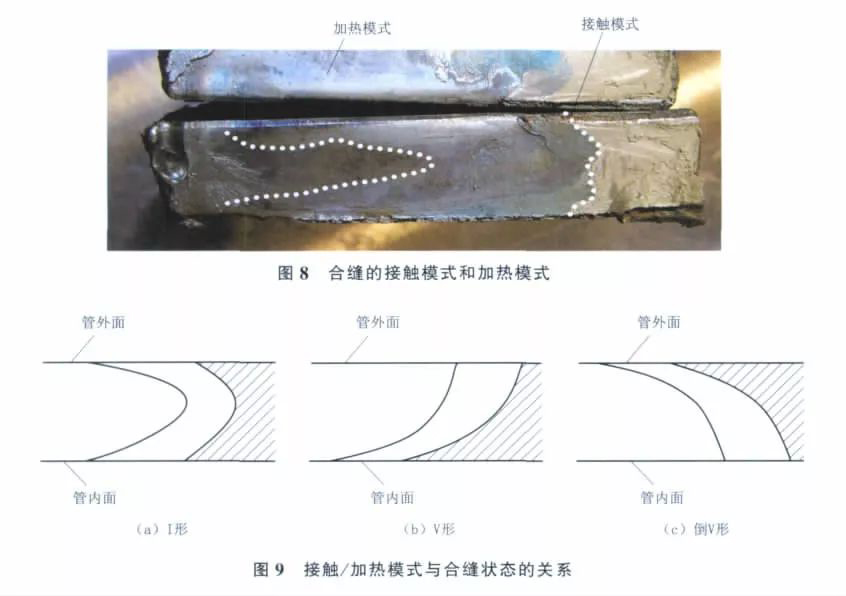

Figures 8 and 9 show the relationship between the contact and heating mode and the seam state

According to this, it is possible to judge the seam state. The contact form and the heating form are in principle the same. The boundary of the contact mode is clear, while the heating mode is more ambiguous, and the judge needs to have a certain experience. However, when the welding extrusion amount is large, the distribution of the contact mode in the longitudinal direction is so short that it is difficult to judge, while the heating mode is not affected by this.

5.Conclusion

In the adjustment and welding of high-frequency welded pipes, through the analysis of the relationship between the contact and heating mode and the seam state of the butt surface, the method of adjusting the upper roll gap and the reduction amount of the welding squeeze roll can accurately and timely ensure the plate of the steel pipe. Edge welding to achieve a good welding state.

(1) When the seam is I-shaped, it means that the butt surface is in a basically parallel state during the welding process, and there is no need to adjust the pressing roller;

(2) When the seam is V-shaped, it means that the lower surface of the butt surface contacts first during the welding process, and the I-shaped state can be achieved by increasing the pressing amount of the upper roller;

(3) When the seam is in an inverted V shape, it means that the upper surface of the butt surface contacts first during the welding process, and the I-shaped state can be achieved by reducing the pressing amount of the squeeze roller.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province