Adjusting the welding seam position of square and rectangular pipes made by used square tube machines (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-10 11:30

- Pvs:

【概要描述】Judging that the quality of the square tube produced by the used square tube machines meets the standard is based on a large number of inspection data of the microhardness of the weld and the microhardness of the base material. The former is much higher than the latter.

Adjusting the welding seam position of square and rectangular pipes made by used square tube machines (2)

【概要描述】Judging that the quality of the square tube produced by the used square tube machines meets the standard is based on a large number of inspection data of the microhardness of the weld and the microhardness of the base material. The former is much higher than the latter.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-10 11:30

- Pvs:

Judging that the quality of the square tube produced by the used square tube machines meets the standard is based on a large number of inspection data of the microhardness of the weld and the microhardness of the base material. The former is much higher than the latter. It is for this reason that the weld is usually not placed at a positive angle, but placed within t~(t+5mm) from the corner edge to reduce the risk of weld cracks. This requires effective control of the weld position. Control methods include forming roll method, guide roll method and sizing roll method.

The following is the introduction of the sizing roll method for the control method of the welding position of the square tube made by the used square tube machines.

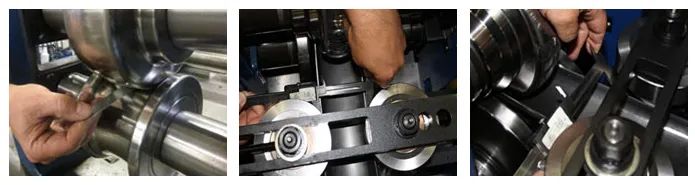

Sizing roll method

Generally, in the design of the square rectangular tube pass roll type, the pass of the first flat roll (or vertical roll) of the sizing is usually designed as a round pass. The sizing roll method is to artificially use the flat roll (or vertical roll) Roll) The hole pattern is adjusted to deliberately misaligned, and the misaligned hole pattern is used to apply a pair of opposite force couples to the welded pipe to promote the directional "rotation" of the tube body of the sizing section to achieve the purpose of controlling the position of the weld.

For example: the upper roll hole pattern is artificially misaligned to the left, the left side of the hole pattern is "empty", only the right side is in contact with the upper right part of the welded pipe, and the welded pipe rotates clockwise under the action of the force on the right side of the hole;

At the same time, the right side of the lower roll pass is "empty", and only the left side is in contact with the lower left side of the welded pipe. The welded pipe also rotates clockwise under the force of the left side of the pass. In this way, under this artificially misaligned two-roller coupling, the welded pipe is twisted clockwise, and then the weld is deflected to the right. Conversely, if the welded pipe is twisted counterclockwise, the weld will be twisted to the left.

According to the principle of mechanics, the sensitivity of controlling the torsion position of the weld, that is, the couple moment, depends on the diameter of the welded pipe and the ± couple (that is, the force and the degree of misalignment of the hole-shaped butt welded pipe). The degree of misalignment is less, and the couple moment is smaller. Less; the greater the degree of misalignment, the greater the torsion of the weld.

The advantage of the sizing roll displacement method to control the position of the weld is: because the deflection of the weld mainly occurs in the sizing section, it has little effect on the welding state of the weld and the removal of internal and external burrs, but it is sensitive to small diameter and thin-walled pipes. Slightly worse (smaller moment of torque), otherwise the pipe surface will be crushed.

Through the control method of sizing roller method, the welding seam position of the square tube made by the used square tube machine is adjusted. However, it must be judged and adjusted according to the actual situation.

What needs special explanation is:

The roll offset is generally only a few tenths of a millimeter to 1~2mm (the smaller the tube is, the smaller the value is), and usually will not crush the tube surface; if the tube surface is indented due to it, this method should be abandoned.

The above-mentioned methods for controlling the position of the weld seam can be used alone or in combination, not only for special-shaped pipes, but also for round pipes.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province