Used EWR tube mills, the influence of operations on welding quality in the production of welded pipes (1)

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-17 11:30

- Pvs:

【概要描述】In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

Used EWR tube mills, the influence of operations on welding quality in the production of welded pipes (1)

【概要描述】In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-17 11:30

- Pvs:

In the production process of used EWR tube mills welded pipe, there are many factors that will affect the final product quality of the welded pipe.

There are 7 factors that affect the welding quality of the welding pipe production operation of the used EWR tube mills, namely ① input heat (ie power KW). ② welding pressure (extruding force). ③ welding speed (unit speed). ④ opening angle (Vee angle). ⑤ The placement position of the inductor (coil) and the resistor. ⑥ the geometric size and shape of the tube blank. ⑦ the quality of the strip edge. the following first introduces the reasons ①~④ that affect the welding quality.

1. Input heat (ie power KW)

Power is one of the main parameters of the welding process, which can be understood as the welding current (or welding temperature). Because the current is difficult to measure, it is replaced by the input heat, and the input heat can be represented by the output power of the oscillator.

When the input heat is insufficient, the heated edge of the strip steel cannot reach the welding temperature, and the solid structure is still maintained and cannot be welded, and welding cracks will be formed;

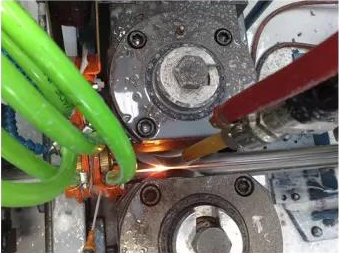

When the input heat is too large, the heated edge will exceed the welding temperature and will easily cause overheating, or even overburning, and cracks after being stressed. Excessive heat will cause the welding temperature to be too high, causing the weld to pierce, causing the molten metal to splash and form holes.

Continuous and stable output power of the welder is an important prerequisite for ensuring the quality of welded pipes.

2. Welding pressure (extrusion force)

The welding pressure is one of the main parameters of the welding process. After the two edges of the tube blank are heated to the welding temperature, the common metal crystal grains are formed under the action of the extrusion force, that is, mutual crystallization to produce welding. The size of the welding pressure affects the strength and toughness of the weld. If the applied welding pressure is small, the metal welding edge cannot be fully pressed together, and the residual non-metallic inclusions and metal oxides in the weld are not easily discharged due to the low pressure, the weld strength is reduced, and it is easy to crack after being stressed; At this time, most of the metal reaching the welding temperature is squeezed out, which not only reduces the strength of the weld, but also produces defects such as excessive internal and external burrs or lap welding. Therefore, the optimum welding pressure should be obtained in practice according to different varieties and specifications.

Excessive or too small squeezing force will affect the strength and toughness of the weld, just like squeezing acne. If the force is small, the squeezing will not be clean, and if the force is too high, the skin will be damaged.

3. Welding speed (unit speed)

The welding speed is also one of the main parameters of the welding process, which is related to the heating speed, the welding seam deformation speed and the mutual crystallization speed. When high-frequency welding is used in the used EWR tube mills, the welding quality improves with the increase in welding speed. This is because the shortening of the heating time narrows the width of the edge heating zone and shortens the time for forming metal oxides. If the welding speed is reduced, not only the heating zone becomes wider, but also the width of the melting zone changes with the input heat, forming an internal The burr is large. In low-speed welding, less heat input makes welding difficult, and defects are likely to occur if the specified value is not met.

When welding pipes with high frequency, the appropriate welding speed should be selected according to different specifications and varieties under the maximum speed allowed by the mechanical equipment and welding equipment of the unit.

4. Opening angle (Vee angle)

The opening angle refers to the angle between the two edges of the tube blank before the squeeze roll. The size of the opening angle is related to the stability of the sintering process and has a great influence on the welding quality.

When the opening angle is reduced, the distance between the edges is also reduced, so that the proximity effect is strengthened. Under the same other conditions, the heating temperature of the edges can be increased, thereby increasing the welding speed.

If the opening angle is too small, the distance from the meeting point to the centerline of the squeeze roll will be lengthened, resulting in that the edge of the steel strip is not squeezed at the highest temperature, which will reduce the welding quality and increase the power consumption.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province