Used welded pipe production line, the influence of heat-affected zone control technology on welding quality

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-11 11:30

- Pvs:

【概要描述】In the used welded pipe production line, high-frequency welding steps will appear, and the quality of high-frequency welding is often affected by the heat-affected zone control technology. For the quality of steel pipe welding, it is necessary to understand the heat-affected zone control technology of the second-hand welded pipe production line.

Used welded pipe production line, the influence of heat-affected zone control technology on welding quality

【概要描述】In the used welded pipe production line, high-frequency welding steps will appear, and the quality of high-frequency welding is often affected by the heat-affected zone control technology. For the quality of steel pipe welding, it is necessary to understand the heat-affected zone control technology of the second-hand welded pipe production line.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-11 11:30

- Pvs:

In the used welded pipe production line, high-frequency welding steps will appear, and the quality of high-frequency welding is often affected by the heat-affected zone control technology. For the quality of steel pipe welding, it is necessary to understand the heat-affected zone control technology of the used welded pipe production line.

The metallurgical definition of high-frequency welding heat-affected zone is:

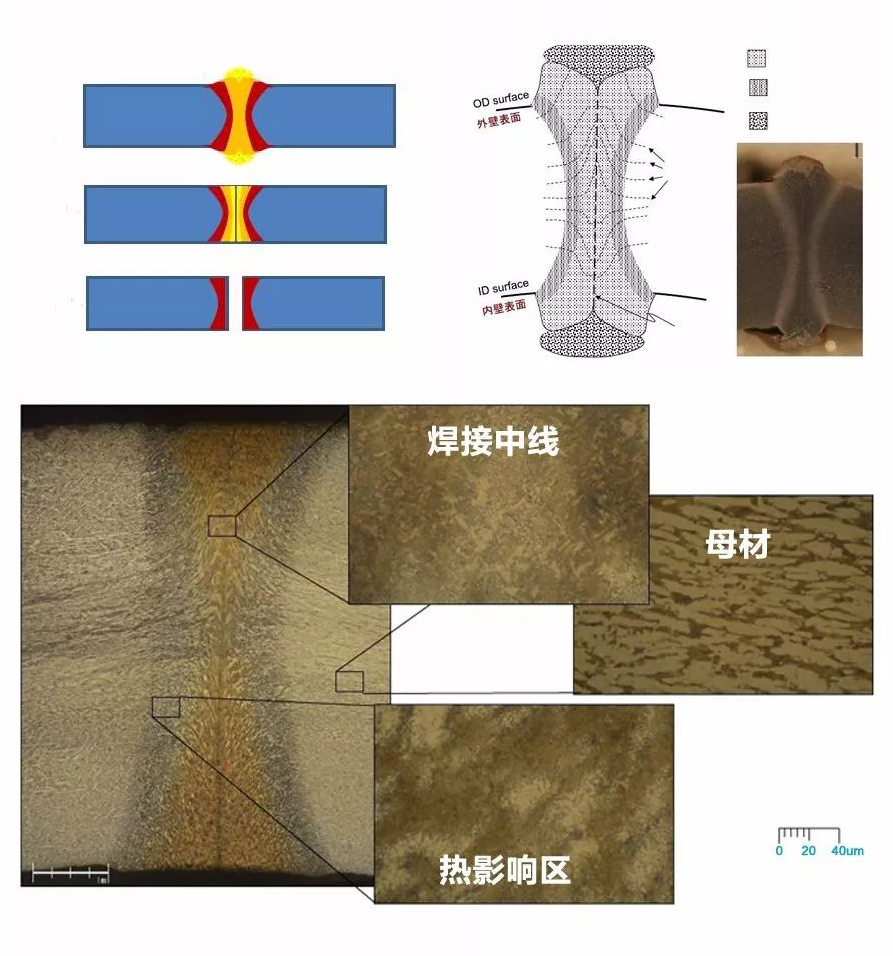

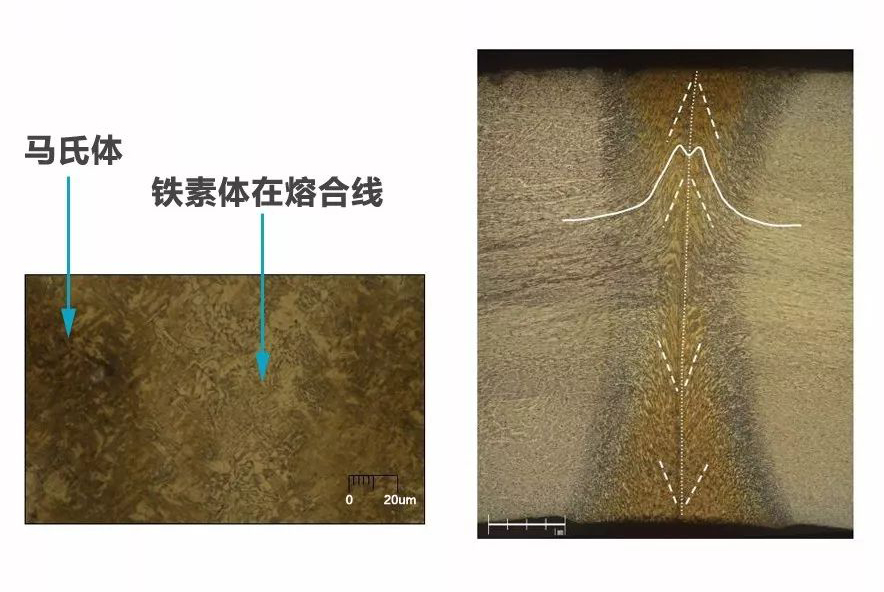

The change area of the structure and properties of the base metal near the weld caused by welding is caused by the temperature change of the welding process and the subsequent cooling process. Different weld structures and base metals have different hardness and toughness, for example, the properties of different parts of the weld area are different. The temperature distribution of the welding V-shaped zone directly affects the structure and grain size of the weld metal, which will significantly affect the experimental results of the material.

Welding temperature changes cause changes in the structure of the weld. The specimens made by cutting and polishing can be observed under a microscope. The structure of the heat-affected zone of the weld profile has obvious changes.

The influencing factors of the heat-affected zone in the used welded pipe production line are many, including:

(1) Plate, diameter and wall thickness of steel pipe;

(2) Unit operating speed and welding power;

(3) Whether to use induction welding or contact welding and welding the length of the V-shaped zone;

(4) The forming quality of the strip edge when passing through the weld;

(5) The design of the welding position and the squeezing force applied by the welding point.

We can pre-set the pipe diameter, wall thickness and pipe material and other parameters before operation. Parameters such as welding power, welding frequency, V-shaped zone length and welding speed are all flexibly set.

By selecting these parameters correctly, a heat-affected zone with good performance can be obtained, thereby ensuring the quality and performance of the steel pipe.

It is very important that the width of the heat-affected zone is not "symmetrical" with the best width, and it is the best measure.

So far, the main properties of high-frequency welds can be inferred from the heat-affected zone, and the structure and performance of the heat-affected zone can be judged based on the welding time-temperature change. Therefore, in order to study the characteristics of the heat-affected zone, it is necessary to understand the law of the influence of unit adjustment on the temperature distribution of the edge of the welded V-shaped zone.

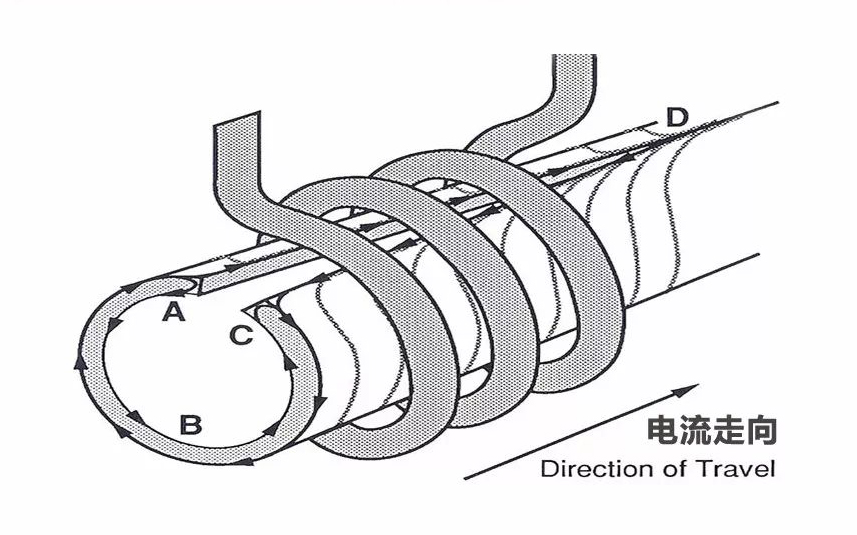

Theoretically, the temperature distribution of the high-frequency welding V-shaped zone is firstly determined by the heat generated by the current flowing through the V-shaped zone. The heat conduction determines the penetration depth of the steel strip edge of the welding zone. The characteristics of the high-frequency current distribution are to look at it. The penetration depth is a function of the welding frequency. The characteristic of the heat conduction process is that the depth of heat penetration is a function of the length of the V-shaped zone and the welding speed.

The actual state of high-frequency welding of steel pipes is:

①The current penetration depth is greater than the thermal penetration depth, which is a result of temperature distribution; ②The thermal penetration depth is greater than the current penetration depth, which is the result of another temperature distribution; ③The thermal penetration depth, which is a transition Temperature distribution status.

In short, establish a time-temperature curve in the welding heat-affected zone of the used welded pipe production line, and combine the high-frequency current heat effect (current penetration depth) and the heat conduction in the welding V-shaped zone (heat penetration depth) to control the temperature distribution in the welding zone. If the current penetration depth and heat penetration depth can be calculated based on some important welded pipe unit parameters (pipe diameter, wall thickness, welding power, welding frequency, V-shaped zone length and pipe performance), then the steel strip edge of the welded V-shaped zone can be predicted This method can accurately predict and control the heat-affected zone of the weld.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province